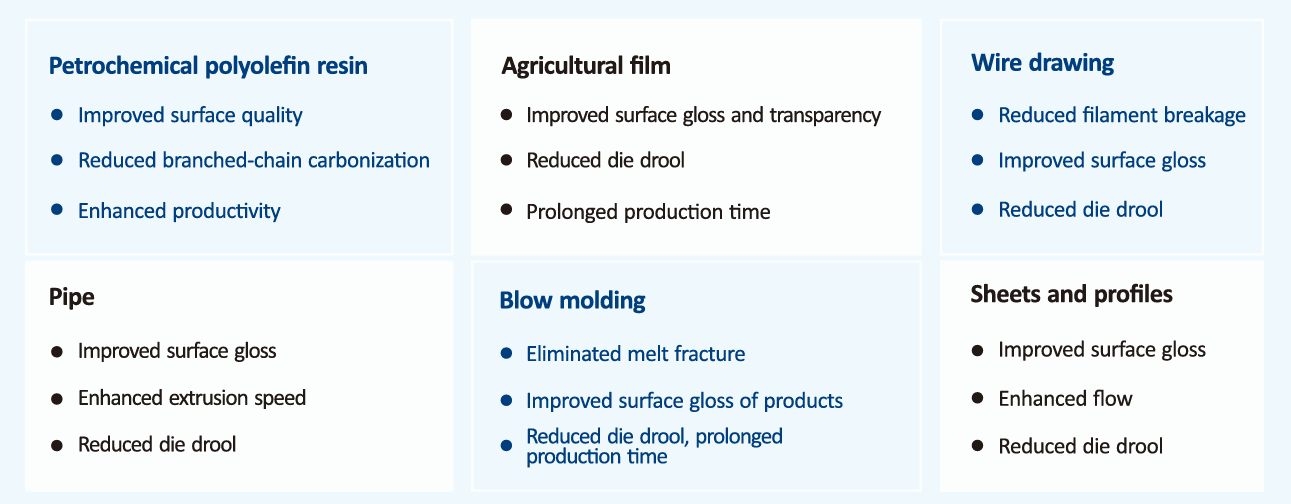

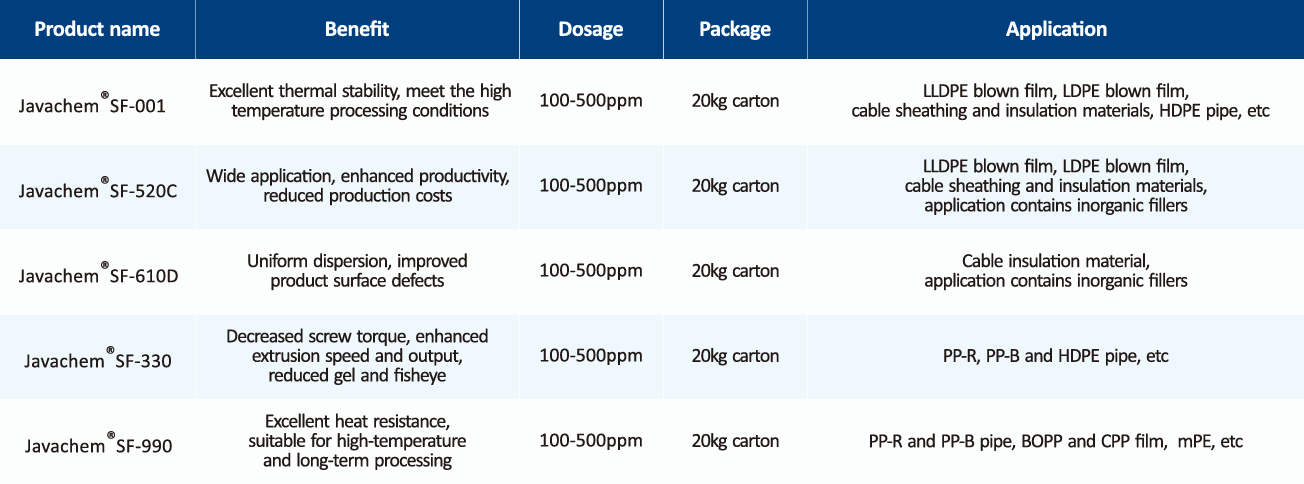

| Javachem®SF is a series of fluoropolymer processing aids based on a new dispersion technology, which can form polymer 'coating' structure with low surface energy in base resin to decrease interface adhesion between polymer melt and die. With characteristics of fast onset, good dispersion, high temperature resistance and non-coking, Javachem®SF provides a comprehensive solution such as eliminated melt fracture, reduced die drool, enhanced throughput and improved surface gloss for high melt-viscosity polyolefins. It is widely used in the processing of polyolefin materials like granulation, film blowing, casting, wire drawing, pipe extrusion, etc. ·International PCT patent PPA production line (annual capacity: 3,000 tons) ·Plastics Industry—2020 Ringer Technology Innovation Award ·Comprehensive process coverage (film materials, pipe materials, injection molding plastics, filament drawing, sheet drawing, etc.) ·Strong market foundation with end-user base across diverse industries; widely adopted by fortune 500 Companies |

Javachem®SF Application advantages:

Zhejiang- ICP- No. 16008341

(C) 2015 Zhejiang Java Specialty Chemicals Co., Ltd. All rights reserved. Javachem trademark, 佳华精化®, Javachem® and related TM or ® are all registered trademarks of Javachem or its affiliates.